How can we help you?

For Your Street Lighting

Your Nema PhotoControl Receptacles

Your Nema PhotoControl Receptacle

JL-200X

All the JL-200 series photocontrol receptacles were designed for the lanterns intended to accept a twist-lockphotocontrol for power management.JL-200 Photocell receptacle

features:Bakelite body for long-life service and Silicone gasket for better waterproof.

This Seires photocell receptacle applicable volt range:0~480VAC.

Rated Frequency:50/60Hz.

Power Loading:AWG#14: 15Amp.

JL-200&JL-200Z have accessories:Back/Front Cover and Zinc Alloy Lock Nut.

This photocell receptacle IP level:IP65.

JL-210K

The JL-210 Photocell Receptacle PECV receptacles were designed for the lanterns those without an BS5972 receptacle.

JL-210 PhotoControl Receptacle is used for lantern assembling,and JL-210K is used for wall-mounted separately.

his JL-210K Photocell socket is CE certified.

Power Volt Range:0~480VAC.

Rated Frequency:50/60Hz.

JL-230F

All the JL-230 photocontrol receptacles are intended to be pre-mounted onto those lanterns designed to fit anANSI C136.10-1996 twist-lock photocontrol.

Both JL-230-16 and JL-230-14 photocell receptacle have been recognized by UL to applicable US and Canadian safety standards, under their file E188110, Vol.2.

JL-240XB

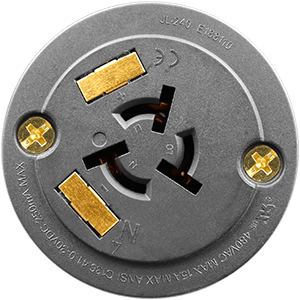

All the JL-240 series photocontrol receptacles were designed for the lanterns those intended to have an ANSI C136.41 receptacle to fit a twist-lock smartcontrol, allow a LED lamp multi-controlled through the receptacle.

This series offers 2 or 4 gold-plated low voltage pads on the top surface to fit photocontrol has ANSI C136.41 conforming spring contacts, and offers male quick connectors at rear back for signal connection.

This series Photocell Receptacle also offers 360 degree rotation limiting feature to conform ANSI C136.10 requirements.Both JL-240X and JL-240Y Street Light PhotoControl Receptacle have been recognized, and JL-200Z14 has been listed by UL to applicable US and Canadian safety standards, under their file E188110, Vol.1 & Vol.2.

JL-240XA/TXA/TLXA

All the JL-240 series photocontrol receptacles were designed for the lanterns those intended to have an ANSI C136.10-2006 receptacle to fit a twist-lock photocontrol. This series conform newly published ANSI C136.41-2013 to allow a LED lamp multi-controlled through the receptacle.This series offers 2 or 4 gold-plated low voltage pads on the top surface to fit photocontrol has ANSI C136.41 conforming spring contacts, and offers male quick connectors at rear back for signal connection.This series also offers 360 degree rotation limiting feature to conform ANSI C136.10 requirements.

Both JL-240X and JL-240Y have been recognized, and JL-200Z14 has been listed by UL to applicable US and Canadian safety standards, under their file E188110, Vol.1 & Vol.2.

JL-240FXA

All the JL-240FXA photocell receptacles were designed for the lanterns those intended to have anANSI C136.10-2006 receptacle to fit a twist-lock photocell light control. The JL-240FXA Photocell Receptacle conform newly published ANSI C136.41-2013 to allow a LED lamp multi-controlled through the receptacle.

This series photocontrol receptacles offers 2 or 4 gold-plated low voltage pads on the top surface to fit Photocell has ANSI C136.41 conforming spring contacts, and offers male quick connectors at rear back for signal connection.

The Photocell Receptacle also offers 360 degree rotation limiting feature to conform ANSI C136.10 requirements.

JL-250T

The entire JL-250T series twist-lock photocell receptacles were designed for the lanterns those which intended to have an ANSI C136.10 receptacle to fit a twist-lock photocontrol.

This series photocell receptacle conforms newly published ANSI C136.41 to allow a LED lamp multi-controlled through the receptacle, and obtained cRUus certificates under UL file E188110.

The JL-250T1412 photocell receptacle offers 4 gold-plated low voltage pads on the top surface to fit photocontrol which has ANSI C136.41 conforming spring contacts, and offers 4 corresponding wires at rear back for signal connection.

This type photocell receptacles offers 360 degree rotation limiting feature to conform ANSI C136.10 requirements. After simply fit its Rear Seat onto a lamp housing with 2 screws, the assembled receptacle body can be handy snapped on the Seat for mechanical installation completed.

Rotation will be held during photocontrol installation or removal by pressure applied vertically.

This type photocell receptacle has multiple gaskets built-in already for IP65 protection.

JL-260C/JL-260D

All the JL-260 series photocontrol receptacles were designed for the lanterns those intended to have an ANSI C136.10 receptacle to fit a twist-lock photocontrol. This series conforms newly published ANSI C136.41 to allow a LED lamp multi-controlled through the receptacle.

This series offers 2 or 4 gold-plated low voltage pads on the top surface to fit photocontrol which has ANSI C136.41 conforming spring contacts, and offers male quick connectors at rear back for signal connection.

This serie photocell receptacles also offers 360 degree rotation limiting feature to conform ANSI C136.10 requirements.

Both JL-260C and JL-260D photocell receptacles have been recognized, and have been listed by UL to applicable US and Canadian safety standards, under their file E188110, Vol.1 & Vol.2.

FAQ About NEMA PhotoControl Receptacle

Q1: What is NEMA 3/5/7 PIN?

A2:NEMA 3 PIN socket is generally used with 3PIN Day Night Light PhotoControl.The NEMA 5 Pin light controller socket is the connector between the light controller and the lamp. NEMA 7 PIN is a connector of NEMA standard interface rotary lock light controller,Used in conjunction with a Twist-lock light controller to control the switch of lamps.

The matching of the light controller and the socket is to realize the automatic control of the lamp switch and reduce energy consumption and manual management costs.

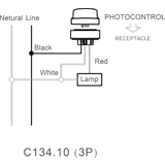

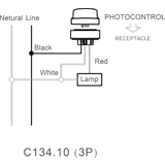

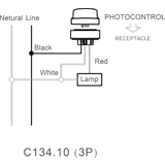

Q2:How to install a NEMA 3 PIN PhotoControl Socket?

A2:Disconnect the NEMA 3 PIN Socket power; wire the receptacle according to the diagram in right hand. An arrow indicating NORTH on the top of the PhotoControl Receptacle is used to assist correct direction. Push the hotocontroller on and twist it clockwise to lock it into the NEMA 3 PIN Socket.Install the photocontroller with the Dusk to Dawn Sensor facing the NORTH direction as indicated on the top of the NEMA 3 PIN Photocontroller.Adjust the PhotoControl Receptacle position by loosening screws and fasten them after its redirected.

Q3: Why use a NEMA 3 PIN Socket?

A3:NEMA 3 PIN sockets are generally used as connectors for dusk to dawn light controllers and lamps, with NEMA standard interfaces

Q4: What is the waterproof rating of the NEMA 3 Pin socket?

A4: Generally speaking, the NEMA 3 PIN Socket waterproof refers to the waterproof after combining with the Photocell Light Controller. A single NEMA 3 PIN socket cannot achieve the waterproof effect.

Q5:How to make the NEMA 3 PIN socket reach a certain waterproof level?

A5:The Day Night Light Controller achieves a certain waterproof level through a special production process (adding foam gaskets, base potting). When the Twist-lock light Day Night PhotoController is connected to the NEMA 3 PIN socket, it can achieve a certain waterproof effect and ensure that the Day Night Light PhotoController is in use During the process, the waterproof performance will be better, the service life will be extended, and the use cost will be saved.

Q6:What is the function of the rotatable light Photocontroller socket?

A6:The rotatable light controller socket is to facilitate customers to flexibly adjust the orientation of the photosensitive window of the light controller. Generally speaking, the installation position of the light controller and the socket is fixed, and each light controller housing has a north-facing sign. After the normal light controller socket is installed on the lamp, basically the position cannot be adjusted. The emergence of the rotatable light controller socket solves this kind of problem, allowing you to adjust the light controller orientation according to your needs.

Q7:What is the difference between 5 Pin Photocell Receptacle and 3 Pin Photocell receptacle?

A7:There is about 90% similar function and material for light controller to automatically light switch. most important dimming output which the 5 pin receptacle 0-10V, and there is others two wires for professional connect dimming driver / steady current driver.

Q8:Why use 5pin Photocell Light controller socket?

A8:Use NEMA 5pin Photocell light controller socket as a standardized interface connector, which plays a role in connecting the Photocell light controller and the street lamp. As a common street light controller, the twist-lock type light photocontroller has a wide range of applications due to its easy installation and standard interface.

Q9:How to use NEMA 7 PIN socket?

A9: Under normal circumstances, NEMA 3pin/5pin/7pin Twist-Lock light PhotoControllers can be used with NEMA 7 PIN sockets.The NEMA 7 PIN Socket has a dimming function, and ordinary light PhotoControllers do not have a dimming function, so generally NEMA 7 PIN Sockets are more often used with NEMA 7 PIN dimming light controls.

Q10:What is NEMA?

A10:NEMA believes that Standards play a Vital part in the design, production, and distribution of products destined for both national and international commerce. Sound technical Standards benefit the user, as well as the manufacturer, by improving safety, bringing about economies in product, eliminating misunderstandings between manufacturer and purchaser, and assisting the purchaser in selecting and obtaining the proper product for his or her particular need.